How Do I Know if My Centrifugal Pump Is Bad

Many businesses and homeowners have found themselves asking, “How do I know if my centrifugal pump is bad?” Some even seek advice and answers to this very question. Centrifugal pumps, the unsung heroes in our homes and industries, often go unnoticed until something goes wrong. Picture this: When a typical day becomes the eventful name of troubleshooting as your pump starts acting up. Frustrating, right?

It is very important to understand the signs of a failing centrifugal pump. It’s like knowing the symptoms of a cold before it becomes pneumonia – prevention is always better than cure. Let’s solve the puzzle of pump failures. We will look at what to watch for, from the smallest signs up to plain red flags, helping you navigate through identifying problems before they become bigger.

Understanding Centrifugal Pumps

Centrifugal pumps are like the diligent workers of the mechanical world, often unnoticed but crucial. They are the heart of many systems, pumping life into various operations. At their core, these pumps move fluids by converting rotational kinetic energy into hydrodynamic energy. Sounds complex. Let’s break it down:

- Essential Mechanics: A motor spins the pump’s impeller, which imparts force on the fluid, propelling it through a pipe.

- Versatile Applications: You’ll find these pumps in everyday scenarios – from the water in your home to complex industrial processes.

- Key Roles in Systems: They’re essential in water supply, wastewater management, irrigation, and even in your heating and cooling systems.

The beauty of centrifugal pumps lies in their simplicity and effectiveness. They are the unsung heroes in seamless operations, silently doing their job and ensuring everything runs smoothly. So next time you turn on a tap or feel the warmth of your heater, remember there’s probably a centrifugal pump working tirelessly behind the scenes!

How Do I Know if My Centrifugal Pump Is Bad?

Something wrong with centrifugal pumps is kind of like hearing a strange noise from your car and thinking, “Something’s not right?” Knowing the signs of a bad pump can help you avoid all sorts of troubles. So, let’s address the question – “How do I know if my centrifugal pump is bad?”, and discuss its unique symptoms.

Unusual Noises: A centrifugal pump should function as smoothly as a well-oiled car engine. If it groans, grinds, or makes sounds like some tired old truck, you should look into the problem.

Visible Leaks: Water where it shouldn’t be? A leaking pump is a call for help. Look for puddles or drips around the pump.

Decreased Performance: When water pressure or flow rate is reduced, it is a clear sign.

Overheating: Just like when we overheat, pumps are liable to the same condition after running all day in hot weather. If your pump gets hot enough that you can’t touch it, this is an indicator of a problem with the pump: either it has to be working too hard or simply isn’t operating as effectively as possible.

Vibration Excess: A slight shake is normal, but if your pump shakes like it’s in a dance contest, there might be some internal issue.

Increased Energy Use: A sudden increase in your power bills can be a very subtle indicator of the same. A weak pump usually draws more power.

What Happens When a Centrifugal Pump Is Blocked?

Imagine trying to drink a thick milkshake using a narrow straw. Frustrating, right? That’s what happens when a centrifugal pump gets blocked. A blockage can turn a normally efficient process into a struggle, impacting the pump and the system it supports. Here’s a rundown of the consequences:

- Reduced Flow Rate: Just like the milkshake scenario, a blockage means less fluid gets through. This reduced flow can hamper operations, especially in industries where precise fluid management is key.

- Increased Pressure and Strain: Blockages create pressure build-ups. It is like someone trying to pull a boulder through the thinnest path takes much effort and, therefore, wears it out.

- Overheating: With increased strain comes heat. First, overheating is bad for the pump itself but can also pose safety risks.

- Potential Damage to the Pump: Continuous strain causes damage. In other words, think about it this way: you’re running a marathon with an injured foot, and sooner or later, something is going to break.

- System Downtime: A clogged pump can effectively stop the entire system like a traffic jam originating from only one car stalled in its place. This stoppage can be costly and disruptive.

- Increased Energy Consumption: The work of a pump is blocked, and it takes more energy in order to do its job. This does not only impact efficiency but can also take a shot at you where it really hurts – your electricity bill.

Blocked centrifugal pump is not just an inconvenience; it’s a bottleneck that affects the entire system. These blockages can be prevented by regular checks and maintenance to ensure your system runs as smoothly, like a straw in a milkshake.

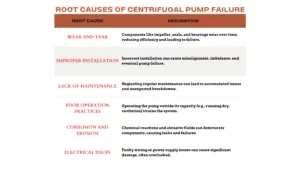

What Is the Root Cause of Pump Failure

Pump failure is like a detective story with several suspects, each with a motive to cause trouble. Understanding these root causes can help prevent the plot twist nobody wants – a broken pump. Let’s unveil the usual suspects in pump failures:

- Wear and Tear: Just like your favorite sneakers start to give in after many miles, centrifugal pumps experience wear over time. The impeller, seals, and bearings are particularly prone to wear, leading to decreased efficiency and potential failure.

- Improper Installation: Imagine assembling a puzzle with a piece in the wrong place – it just doesn’t work right. Similarly, incorrect installation of a pump can lead to misalignment, imbalance, and eventual failure.

- Lack of Maintenance: Neglecting pump maintenance is like skipping car services; it might run for a while, but problems will pile up. Regular checks and servicing are crucial to catch issues early.

- Poor Operation Practices: Operating a pump outside its intended capacity is like driving a car in the wrong gear – it puts unnecessary strain on the system. This can include running the pump dry, cavitation, or operating at the wrong speed.

- Corrosion and Erosion: Just as rust can eat away at the metal, chemical reactions and abrasive fluids can deteriorate pump components, leading to leaks and failures.

- Electrical Issues: Faulty wiring or power supply problems can be silent culprits, often overlooked but capable of causing significant damage.

Each of these factors is a piece in the puzzle of pump health. Addressing them can mean the difference between a well-functioning pump and an unexpected breakdown. Regular maintenance, proper installation, and correct operation are your best bets in keeping your pump running smoothly and the detective story at bay!

Preventive Measures and Maintenance

Maintaining a centrifugal pump is a bit like caring for a car – regular check-ups and timely upkeep can keep it running smoothly for years. But how exactly do you maintain a centrifugal pump?

Regular Inspections: Just as a doctor check-up can spot problems before they turn catastrophic, regular inspections should be able to do the same. Check for any signs of wear, leaks or irregular noises.

Keep It Clean: Clean the pump and the area surrounding it. Debris and dirt may lead to jamming or overheating. Imagine it to be as if you have a clean environment which helps in increasing efficiency at work.

Lubricate Bearings: Lubricating the pump’s bearings will reduce friction and wear, just like oiling a squeaky hinge. This small thing can contribute to the longevity of your pump.

Check Alignment and Balance: Smoothly propelling a bike wheel is like having your pump well aligned and balanced.

Monitor Pump Performance: Performance indicators such as flow rate, pressure and power consumption should be monitored. This is similar to checking the speedometer and fuel gauge while driving.

Prevent Cavitation: Stay away from circumstances leading to cavitation, such as potholes on the road. This would also include ensuring correct fluid levels and that the pump operates at its design limits.

Schedule Professional Servicing: As you sometimes need a mechanic for your car, think about having pump services done by professionals occasionally. They can locate issues that you may easily miss and do complex repair jobs.

These prophylactic precautions are essential for preventing pump failures and the most effective operation performance possible over a long time. For instance, maintenance such as that of contributing towards the health of your pump – a little now is equivalent to preventing oneself from facing various issues later.

Pump Perfection with Platinum Performance

During our quest to provide an answer regarding “How do I Know if My Centrifugal Pump Is Bad,” we have explored the symptoms of a failing pump, what happens in case there are blockages present in it and why centrifugal pumps fail due to one or another reason. Regular health surveys, timely response to unique symptoms and adherence to good maintenance habits are your best friends in making sure that the lifespan and effectiveness of your pump.

Avoid being caught off-guard by pump problems. Embrace proactive maintenance and awareness. With our professional help, your centrifugal pump will be in the best shape to face whatever comes its way. Reach out to Platinum Performance Products if you need guidance, maintenance or anything pump-related. Your pump deserves the best, and so do you.