How Do I Choose a Bearing Housing: 8 Important Considerations

The selection of bearing housings can be complex, but it’s not impossible. Bearing housings have a huge impact on your machine’s performance and should only be selected after careful consideration. If you’re asking, “How do I choose a bearing housing?” This article will discuss the kinds of bearing housings and what to look for when choosing them.

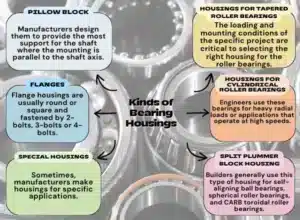

Kinds of Bearing Housings

Bearing housing is fairly important, and there are many kinds. You can pick the one that best suits your needs. We have five described below.

Pillow Block – Pillow blocks, also known as pedestal housings, are the most common form of housing for mounted units. Manufacturers design them to provide the most support for the shaft where the mounting is parallel to the shaft axis. Pillow blocks come in many configurations, usually with bolt holes that you can adjust when mounting. There is also a product called pressed steel pillow block bearings, which are for light applications.

Flanges – The second most common type of housing is flange housing. Flange housings are usually round or square and fastened by 2-bolts, 3-bolts or 4-bolts. Take-up units, an efficient way to tension the pulleys of conveyor belts or elevator applications, are either tension or push. Rod-end units have an eye-shaped head with a shank that makes the housing for a spherical plain bearing. Rod-end units are either shoe or “T” types.

The rod-end housing comprises a split outer shell that encases a bearing set in a swivel cartridge. Manufacturers typically make standard rod-ends out of grey iron. Graphite iron or steel are available. Flanges also come in hanger mountings. Manufacturers design hanger mountings as single-boss, double-boss, or triple-boss hangers.

Special Housings – Sometimes, manufacturers make housings for specific applications. For example, the manufacturer of the water-cooled housing designed it specifically for the steel mill industry’s use with continuous casters. You can request that manufacturers design special housing for specific projects.

Housings for Tapered Roller Bearings – Engineers use tapered roller bearings for material handlers and processors, air-handling equipment, water and waste treatment, shredders, ovens, and furnaces, to name a few applications. The loading and mounting conditions of the specific project are critical to selecting the right housing for the roller bearings. For example, if the load sits at an angle into the split of a 2-piece housing, you will need the force of the mounting bolt’s clamp strong enough to resist any slippage.

Housings for Cylindrical Roller Bearings – Manufacturers design most cylindrical roller bearings in a single row with a cage. They are, however, available in many sizes and shapes. Engineers use these bearings for heavy radial loads, applications that require rapid acceleration, or applications that operate at high speeds. The appropriate housing for cylindrical roller bearings depends on the project’s operating conditions. Engineers recommend one-piece housings for crane support wheels, wheel hubs, crank bearings, conveyor rollers, rope sheaves, electric motors, pumps, and tension pulleys. Engineers recommend one-piece or split housings for heavy rail vehicles, transmission drives, and dryer cylinders.

You can buy bearing housings made of ductile iron or cast iron. Lighter applications may require pressed steel. Manufacturers also use aluminum to make bearing housings. Aluminum requires a tighter fit because it tends to expand when heated.

How Do I Choose a Bearing Housing?

After purchasing a bearing, you may need to choose housing. Housings are frames that are made to secure and support bearings. You can put a bearing inside of a housing. When installed, the housing will allow the bearing to move while protecting it from damage. What should you look for when choosing bearing housing?

Bushings

Bearing housings can be used with and without bushings. Bushings are vibration isolators. They absorb and isolate the vibrations produced by the parts with which they are used. Some bearing housings have a plastic bushing. While the connected part moves, the plastic bushing isolates and absorbs vibrations. Regardless, some bearing housings include a bushing, whereas others don’t.

Thermoplastic Polyester

Instead of choosing a bearing made of a traditional metal material, get a bearing made of thermoplastic polyester. Thermoplastic polyester is a synthetic material that offers several advantages over traditional metal materials like aluminum and steel. It’s durable, resistant to corrosion, and offers excellent mechanical strength.

Maintenance Requirements

Some bearing housings need different maintenance steps than others. You might have to clean a bearing housing, for example. Alternatively, you might have to lubricate it with oil. But maintenance-free bearing housings are also available. If you’re tired of constantly lubricating or cleaning your bearing housings, choose a maintenance-free bearing housing.

Flange vs. Pillow Block

Bearing housings are available in various styles, such as flange and pillow block. Flange-bearing housings are known for their flat design. Pillow block bearings, however, are known for an upright, vertical design. The opening in a pillow block bearing is upright.

Fasteners

How many fasteners are required to install the bearing housing? Generally, bearing housings use threaded fasteners for installation. You can insert a set of threaded fasteners through the holes in the bearing housing and into the surface underneath. Typically, bearing housings have two holes — one on each side — for threaded fasteners. However, four-belt flange-bearing housings have four holes, which support four threaded fasteners for installation.

Color

You can find bearing housings in various colors. Black is probably the most typical color in which they are made. It offered a modern and clean appearance that matched most other parts. You can also get bearing housings in white, though. The color will not affect the mechanics of a bearing housing, but it will affect its aesthetics. Therefore, you should select a bearing housing in an appropriate color.

Speed

The speed at which the housing is expected to spin can affect bearing selection and design. For example, if you want your product to spin at high speed throughout its lifetime (e.g., for cutting or sanding), select a faster-spinning bearing that can withstand higher loads with minimal damage. However, it only needs to spin slowly (e.g., for polishing applications). In that case, you may want cheaper, smaller bearings that only wear out slowly and can handle lower speeds without causing problems like chatter or excessive noise levels when used on rough surfaces like wood or metal.

Balance

The same goes for those with engines with high RPMs: if you want the pistons moving smoothly without any loss of power due to friction buildup, then having balanced shafts will help reduce this problem as well!

Bearing housings are critical components of almost any machine, and the right one will last longer and perform better than one that isn’t. That’s why they should be selected carefully to suit specific applications. Bearings are selected based on the type of housing, shaft size, and speed. The application also plays a role in bearing selection, with balance being important if the housing will be carrying weight.

We at Platinum Performance Products offer a wide range of replacement bearing housings. Please reach out to us today.